MISSION

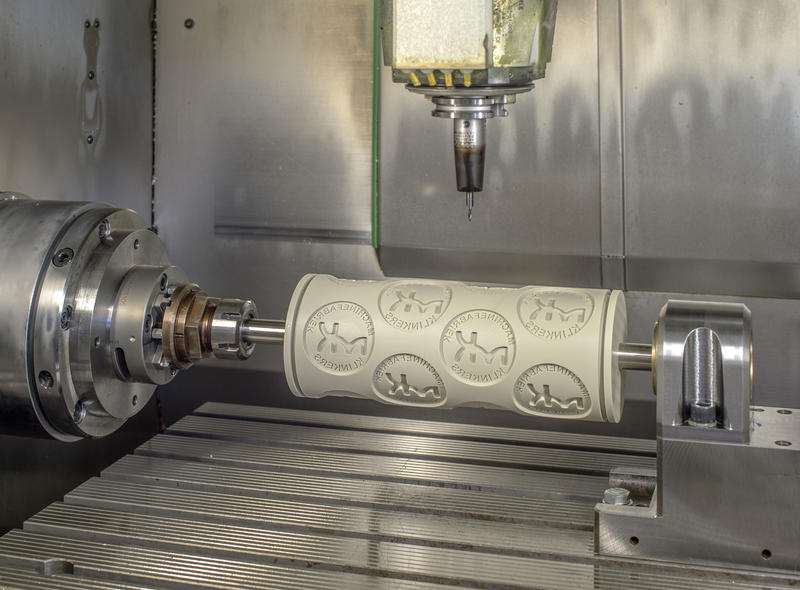

To its clients, Machinefabriek Klinkers is a highly motivated and flexible partner. Extra value is added by focussing on a reliable supply of high-end complex products.

VISION

Machinefabriek Klinkers aims to be the best company in its sector.

STRATEGY

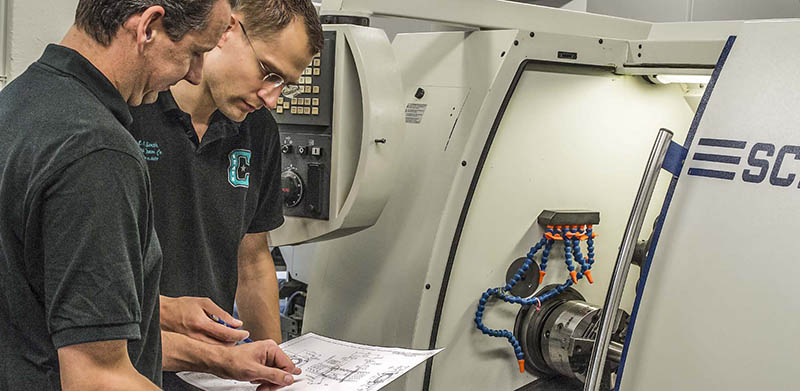

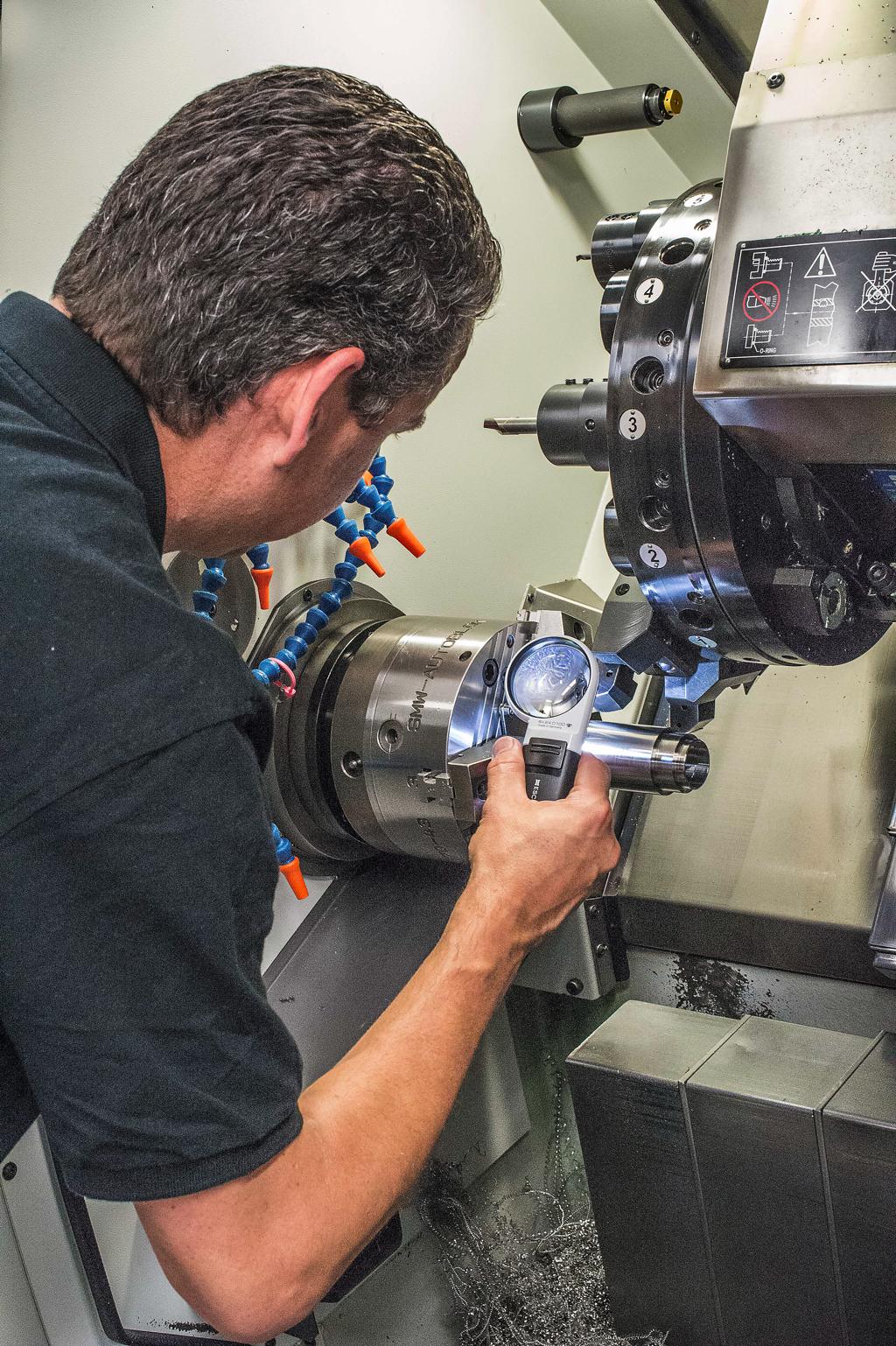

Machinefabriek Klinkers sets its goals by painstakingly keeping track of its customers and their wishes. Objectives are achieved by following a measurable schedule. The quality is guaranteed by continuously investing in motivated employees and qualitatively advanced technology. Machinefabriek Klinkers is always looking for perfection while staying customer-oriented.

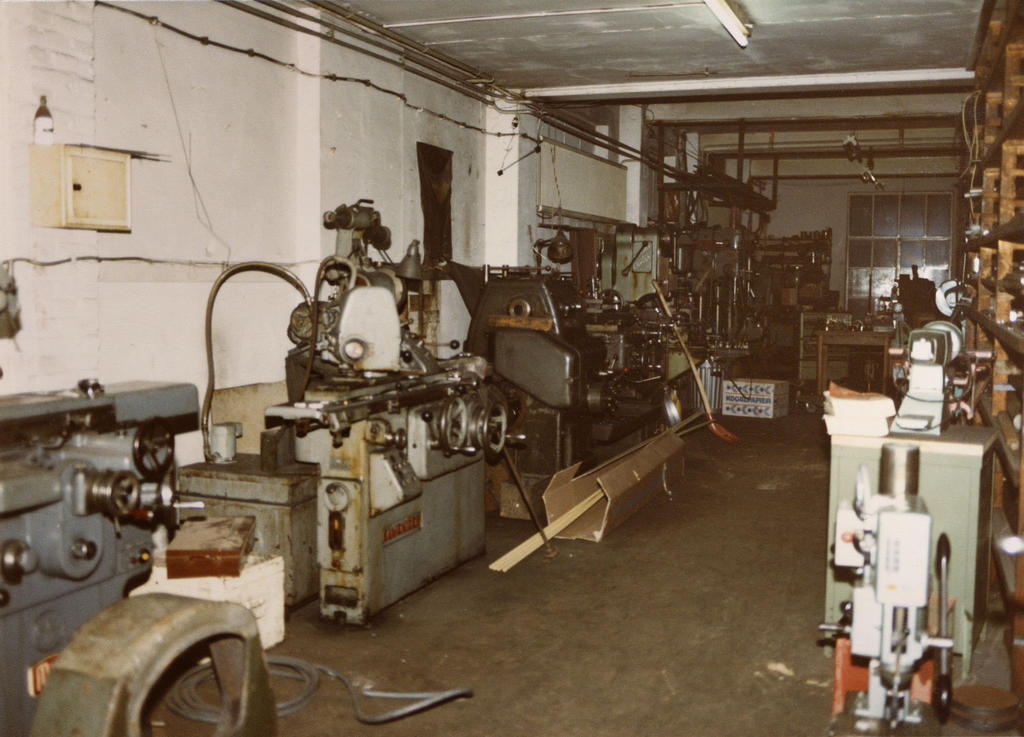

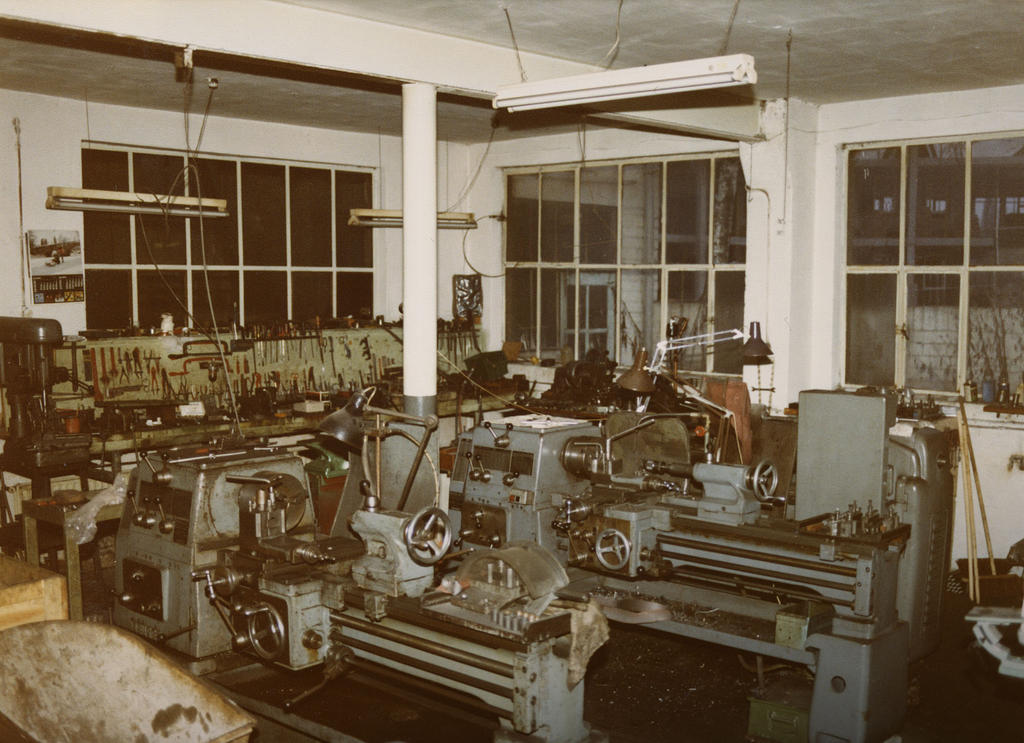

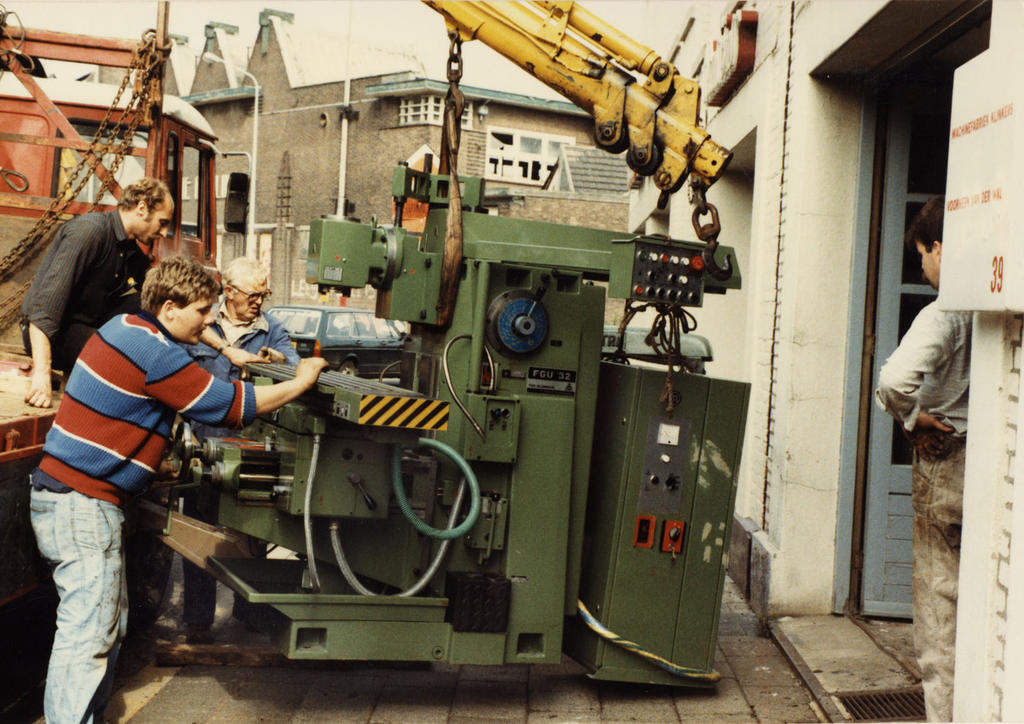

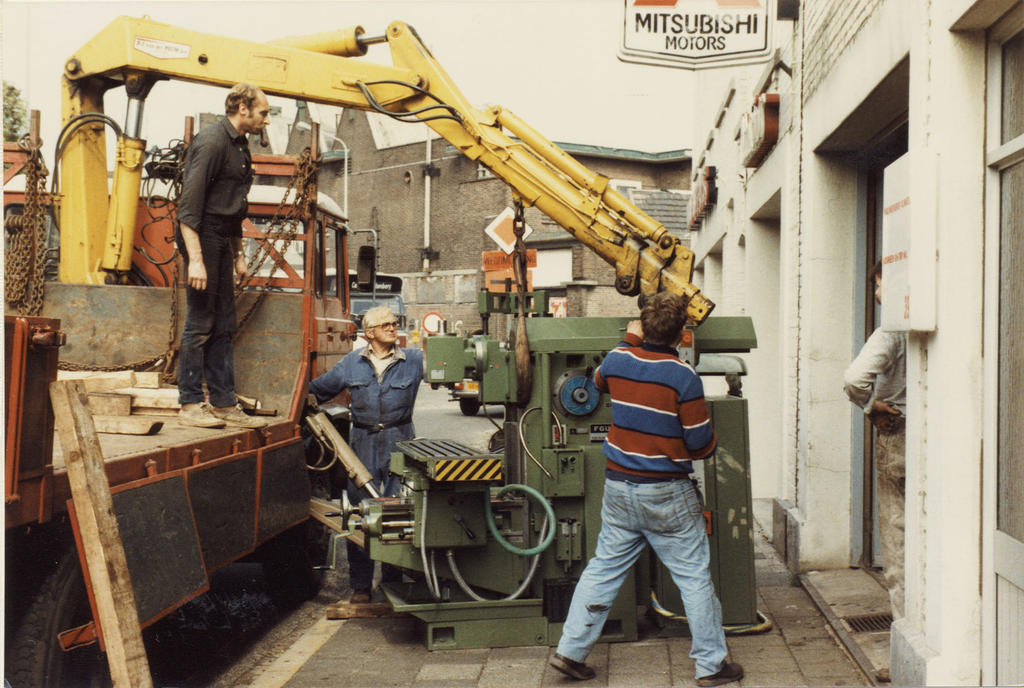

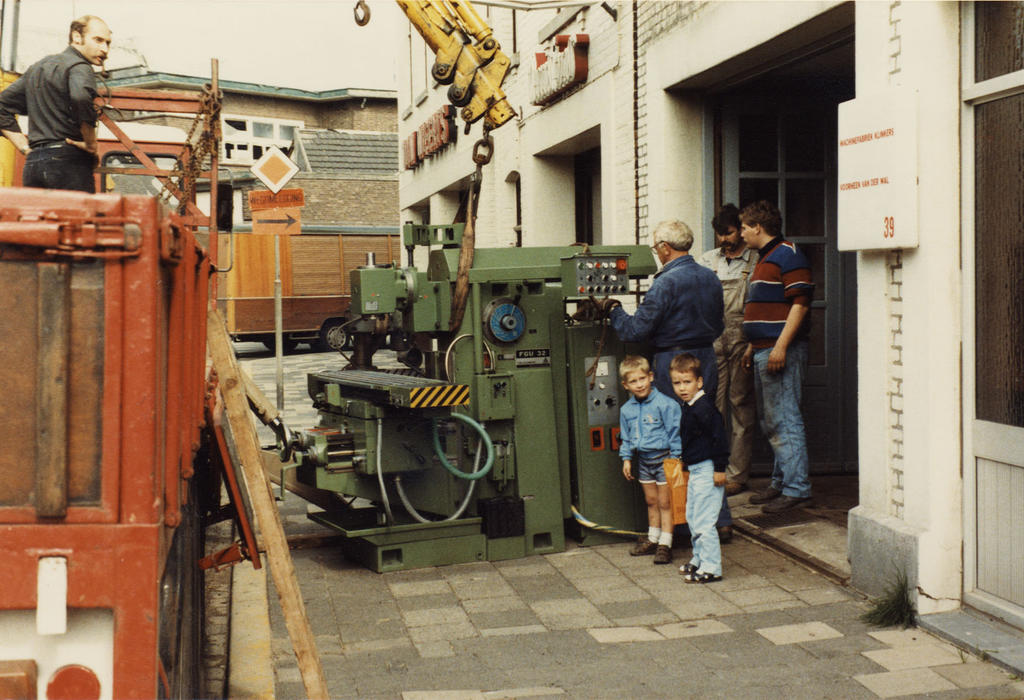

Machinefabriek Klinkers is a family business which was founded by Hans Klinkers in 1985. After being director of a stone factory for about a decade, he bought a workshop from a retired fitter.

With his passion for technique he managed to transform this old workshop into a modern company. In 1994 this company outgrew the location on the Heugermerweg in Maastricht and moved to a larger and more modern building located on the Heerderdwarsstraat, also in Maastricht. This is where the company can still be found today.

Over the years, the activities evolved from mechanical engineering and repairs to precision engineering and series production. Since 2005, the high-tech industry plays a growing role of importance within the company. In 2011, Hans Klinkers handed over the general management of the company to his son Jeroen, who has degrees in both mechanical engineering and engineering management. Hans remains active on the background of the company in the area with which it all started: a passion for technique

To us, quality means supplying the products and services that meet the wishes and demands of our customers. By quality we mean delivery reliability, price, technical accuracy and honoring our commitments.

Not only because of the far-reaching demands from our clientele, but also from our own conviction, we have been ISO9001 certified for years (TUV Nord).